The Heat and Frost Insulators Labor Management Cooperative Trust promotes mechanical insulation and firestopping initiatives.

As clean energy and climate change make a larger impact on the industrial sector and the construction industry, mechanical insulation should be a component of all clean energy initiatives.

Mechanical insulation is the single most overlooked and undervalued energy efficiency and energy sustainability concept within engineered building facilities in America.

Professionally installed and maintained mechanical insulation can save millions of dollars in energy utilization with a short return on investment. By using less energy, buildings and facilities will not only reduce the carbon footprint and benefit the environment, but quickly realize a return on the investment. Mechanical Insulation Energy Audits (MIEA) measure the performance of insulated mechanical systems and offer tangible written data to verify cost savings, energy savings and environmental impacts. It can also be used to develop a clear and pragmatic campaign for strategic sustainability.

Engineers, architects and facility owners must constantly be aware of their mechanical systems and the insulation installed on them. It is imperative that new construction, upgrades and maintenance projects incorporate the latest technology and insulation products and ensure the insulation products are installed according to engineered required specifications.

The truth is that only a few insulated systems are correctly inspected for performance.

Energy audits can be performed at many different levels to meet the need of facility managers. Data is collected and entered into the 3Eplus computer program, which was developed through the U.S. Department of Energy. The results are astonishing as they physically show the amount of energy wasted from not realizing and enforcing the value of mechanical insulation. As part of the maintenance of their mechanical systems, building facility managers should have a relentless awareness of mechanical insulation.

The cost savings of Mechanical Insulation

The “Return on Investment” (ROI) for the installation or repair of mechanical insulation is usually between six months to two years. Simply put, mechanical insulation has the best ROI because of its instantaneous results, which quickly convert the cost to install and maintain the product into annual savings for decades to come.

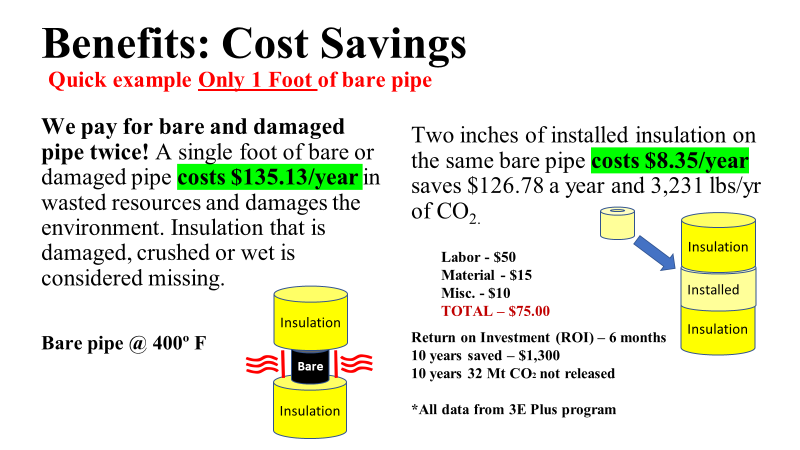

As an example, the illustration compares a 1-foot section of 400 oF bare pipe without pipe insulation to a pipe the same size that is covered with 2 inches of mechanical insulation.

As an example, the illustration compares a 1-foot section of 400 oF bare pipe without pipe insulation to a pipe the same size that is covered with 2 inches of mechanical insulation.

Even though the piece in the example is only 1-foot in length, you can multiply that with the amount that is missing in a typical industrial plant. In a medium-sized plant, an energy audit could easily locate 1,000 feet of pipe insulation that is either missing or damaged – this includes uninsulated valves and other connectors.

On a conservative estimate with this example, 1000 feet of missing or damaged mechanical insulation will cost about $126,780 in a given year. Over the course of a decade, about $1.2 million is wasted. Again, this is a conservative example and many considerable variables will dictate the actual savings.

An MIEA performed by a certified appraiser can provide a more focused evaluation. Regardless of the scope of linear or square footage of a mechanical system, it will give an analysis of the ROI, which is usually within the range of six months to two years. Once the project has paid for itself, the owner then retains 100 percent of the savings. For more information about MIEAs, please refer to the Mechanical Insulation Energy Audits page on the LMCT website.

Mechanical Insulation is an engineered science that must be utilized and maintained on all mechanical systems, regardless of their environmental climate temperatures.

Outside Temperature Does Not Affect ROI

Winterization is protection from the harsh elements of winter, which differs from green energy, clean energy or energy efficiency – year-round accountability of energy consumption.

There is a common misconception that Mechanical Insulation is not needed or will not create a significant ROI in a warmer climate compared to a colder climate. However, this thought process is not true. Over the past few years, there have been numerous articles attributed the grid’s lack of operations to produce power because pipes were frozen due to an unusual drop in temperature. While this can be easily attributed to a lack of weatherization, it is also equally important to understand that it is an indication of a larger concern – these mechanical systems are not utilizing mechanical insulation to conserve energy.

Regardless of the threat of freezing, responsible energy stewardship means Mechanical Insulation must be properly installed as hot pipes exposed in warmer climates are subject to considerable unnecessary energy loss. The same can be said about cold pipes in cool climates. In both instances, exposes or improperly covered pipes will increase the cost of energy and result in a higher operational cost, plus release unnecessary greenhouse gas emissions into the atmosphere.

Hot and cold are relative terms, as what is considered cold in Texas may not be considered cold in New York. Take it a step further, as what is considered cold in New York may not be cold in Alaska. While the various regions of North America have different natural weather attributes, Mechanical Insulation is designed to retain and conserve energy in all climates.

For instance, this is a basic Mechanical Insulation Energy Audit that compared a mechanical 8-inch pipe at 300 0F in New York City to the same pipe located in mid-Texas. Although the average temperature of the regions differ, the energy savings are only slightly different. This goes to show that from a geographical standpoint there is no major difference in the results of properly installed Mechanical Insulation. However, the data shows Mechanical Insulation must be used to conserve energy, regardless the region’s climate.

|

|

Austin, Texas |

New York, New York |

|

Annual average temperature |

72° F year-round average |

55° F year-round average |

|

Example of an industrial pipe |

8 " IPS |

8" IPS |

|

Surface temperature of pipe |

300°F bare pipe |

300°F bare pipe |

|

Operation pipe cost 90% of year without insulation on the pipe |

$113.85 per foot per year |

$121.12 per foot per year |

|

Operation pipe cost 90% of year with 1.5” fiberglass on pipe |

$6.33 per foot per year |

$6.70 per foot per year |

|

Saving per foot per year |

$107.52 |

$114.42 |

|

50' of bare pipe and bare valves |

$5,376 |

$5,721 |

|

100' of bare pipe and bare valves |

$10,752 |

$11,442 |

|

Return on Investment (ROI) |

6 Months to 2 years |

6 Months to 2 years |

|

After ROI next 10 years savings |

||

|

1.5" fiberglass installed 1' of pipe |

$1,075.20 |

$1,144.20 |

|

50' of bare pipe and bare valves |

$53,760.00 |

$57,210.00 |

|

100' of bare pipe and bare valves |

$107,520.00 |

$114,420.00 |

|

All data used for basic calculations were the same except for the annual average temperature of the two cities. |

||

Another common misconception about Mechanical Insulation is that it is too expensive to install. As mentioned earlier, the ROI to install and maintain Mechanical Insulation is anywhere from six months to two years, and after that, it is all savings. Compare the cost of installation to the cost of lost savings and the results speak for themselves.

Damaged or Wet Mechanical Insulation Should Be Replaced for Better ROI

Up to this point, we have discussed the impact of Mechanical Insulation on a bare pipe, including newly installed pipe systems, but there are other instances where Mechanical Insulation can make a difference.

Pipe insulation can be removed, it may deteriorate or it could sustain damage. In other instances, repairs to existing pipe, insulation exposed to weather or improperly installed insulation could negatively impact the performance and ultimately the savings Mechanical Insulation can offer.

It is imperative to understand that damaged Mechanical Insulation is not effective. In fact, the pipe might as well not be insulated. Fibrous insulation only works when the engineered air space is not compressed, wet or compromised. Moisture and insulation will also render Mechanical Insulation useless, as wet insulation becomes a conductor of heat.

In other instances, someone with a good intention to save costs on a construction project may use misguided information and make a decision to not insulate a portion of a system or the entire system. These are key components of understanding the concepts needed to maintain your mechanical insulation systems.

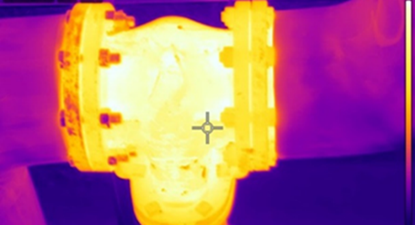

The two images are of a typical uninsulated steam gate valve. It is very common to see uninsulated valves because someone has made a decision not to insulate them.

Often times, when one valve is not insulated, there many others are not insulated as well. The infrared image shows the energy loss (heat loss) from the valve as compared to the adjacent insulated pipe. This is the type of validated visual proof a MIEA can offer, along with additional data to generate numerical values to calculate energy loss, the cost of energy loss and release of greenhouse gas emissions. Typically considered “not a big deal,” the results of a MIEA will detail not just the results of one uninsulated steam gate valve, but all steam gates valves within the facility. The MIEA will prove it is a big deal and demonstrate a significant reduction in operating costs. The true value of the MIEA is to demonstrate the need and the awareness of the valuable power of insulation. Once the concept is understood, MIEAs may no longer be necessary because the concept to insulate mechanical systems is realized.

For plants that currently utilize Mechanical Insulation, routine or preventative maintenance of the Mechanical Insulation will ensure energy efficiency in an industrial plant. Routine inspections will check for the following:

- Insulation was installed to the correct requirements of the system engineered specifications and manufacturer guidelines.

- Proper insulation type installed with the correct thicknesses.

- Insulation was replaced when mechanical service was performed.

- Commonly abused and damaged insulation is repaired.

- Weather Barriers and Vapor Retarders were installed to reduce Corrosion Under the Insulation (CUI).

- Jacketing has proper water shed to prevent insulation water damage and also improve CUI.

Just like any mechanical system needs to be maintained, so does Mechanical Insulation. Without routine maintenance, your system and insulation will not function efficiently. A MIEA starts with a physical inspection to evaluate what and how much Mechanical Insulation is missing or damaged. This is a key component to calculating the potential energy savings of a fully insulated system.

The truth is a mechanical system will work without insulation, but it will function at very inefficient levels. An uninsulated mechanical system or a system with damaged or missing Mechanical Insulation is similar to a refrigerator with its door open. For instance, a refrigerator will continue to work and keep food relatively cold if you kept the refrigerator door open; it would just be very expensive to run and its longevity (life cycle) will be vastly reduced. A mechanical system without insulation runs longer and harder than it should, which in turn reduces its lifespan.

Other types of cost saving factors associated with the MIEA include, but not limited to:

- An increase life cycle for the mechanical system.

- Reduction of corrosion and CUI.

- The ability of the mechanical engineered system to operate at its optimal operating temperature.

Properly Installed Mechanical Insulation Provides a High ROI

When it comes to the mechanical insulation used, it is imperative that the engineered insulation specifications are adhered to either by the specifications of the designed system or by the insulation manufacturer. This ensures that the proper product is installed at the proper thickness to maximize efficiency and does not waste material or money.

Often, Mechanical Insulation is dismissed as a “nice addition” rather than a vital cost savings and energy-efficient commodity.

We need to change that paradigm, as incomplete or poor craftsmanship will affect the efficiency of the insulation. It is imperative to use quality contractors who employ highly trained and highly skilled craftsmen to correctly and professionally install Mechanical Insulation.

While there are cheaper ways to install it, these other options cannot compete with the superior and long-lasting results performed by a highly trained and experienced workforce. Visit the LMCT website for more information about our affiliated contractors.

It has been widely repeated that about 10 percent to 30 percent of all buildings in the U.S. are missing Mechanical Insulation. It is easily understood how that can happen when all the variables discussed earlier are considered. There is a level of serious commitment needed to properly maintain a plant’s energy efficiency, but once the reward is understood and valued, it is worth every penny as huge financial impact can be achieved. For example, a typical five-story hospital contains over 17 miles of insulated pipes, and there are many more miles of pipe in a large industrial plant. Over the course of a decade, the ROI, once the pipes are insulated, is significant.

In today’s industrial market, clean energy, climate awareness and environmental stewardship are at their highest point, as many of us can remember. Mechanical Insulation plays a huge role in protecting the environment.

Think about it, the less a mechanical system has to work, the less fuel is consumed. Hence, less pollution is generated, which therefore reduces the release of harmful greenhouse gas emissions into the atmosphere.

Think about it, the less a mechanical system has to work, the less fuel is consumed. Hence, less pollution is generated, which therefore reduces the release of harmful greenhouse gas emissions into the atmosphere.

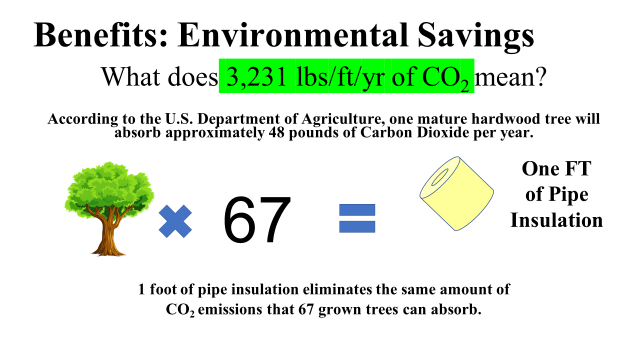

Few people consider Mechanical Insulation a factor to help the environment, but it does. A MIEA can provide the data to show the positive environmental impact the installation of Mechanical Insulation can make at a certain facility. This illustration is based on the example of a properly insulated 1-foot piece of pipe. This is a simple calculation, but it offers a perspective that only a few people think about when considering how Mechanical Insulation actually relates to the environment.

There is no doubt energy technology will lead us to a path of alternative fuel sources, but we must be realistic and reasonable regarding the timeline of those expectations.

How long will it take for a return on investment when it comes to the use of alternative forms of energy, especially as some of those alternatives are yet to be developed or built?

For the foreseeable future, the U.S. will continue to depend on fossil fuel for energy use in commerce and transportation, but efficient use of these energy types is good stewardship. Using energy-efficient technologies now will offer insurance with a successful transition into 21st-century energy goals.

We cannot become too green too fast.

In the meantime, by investing in Mechanical Insulation, you will obtain an ROI that other alternatives cannot match.

For further information and resources, contact Pete Ielmini, LMCT Executive Director, at pielmini@insulatorsLMCT.org.

Comments